Schaeffler at EASA 2023 (Booth No. 1100) Schaeffler Exhibits Advanced Bearing and Condition Monitoring Innovations for Electric Motors at the EASA 2023 Convention and Solutions Expo

2023-06-22 | National Harbor, Md.

- Specially engineered FAG current-insulating bearings from Schaeffler that are designed to prevent electrical current from causing damage

- OPTIME Ecosystem that combines Schaeffler’s award-winning OPTIME condition monitoring system with the OPTIME C1 smart lubricator

- Schaeffler’s smart induction heaters that can safely heat a broad range of components weighing as much as 1,600 kg/3,527 lbs.

Leading global automotive and industrial supplier Schaeffler is presenting a variety of advanced innovations for electric motor manufacturers and rebuilders at the EASA 2023 Convention and Solutions Expo, which takes place June 25-27 at the Gaylord National Resort & Convention Center in National Harbor, Maryland.

Commenting on Schaeffler’s array of products and innovations on display at EASA 2023, Ryan Lynch, power transmission business unit director for Schaeffler in the Americas, said, “Motor reliability and motor uptime are key issues for our customers, which is why we are so excited to offer solutions such as our hybrid ceramic bearings. Their ability to prevent the passage of electrical current can significantly extend grease life, thereby increasing the reliability and mean time between bearing and, by extension, electric motor failures.” Dr. Felix Tenner, vice president for Schaeffler Lifetime Solutions in the Americas, added, “We are also very proud to introduce the EASA audience to our ingenious OPTIME Ecosystem, which combines Schaeffler’s longstanding expertise in the fields of bearing technology, vibration analysis and lubrication with a user-friendly product design that is geared toward the day-to-day tasks of maintenance teams.”

Among the Schaeffler highlights on display at EASA 2023:

Current-Insulating Bearing Solutions

Electrical current passing through bearings can lead to premature bearing failure and expensive machine downtime. FAG current-insulating bearings – including hybrid ceramic or ceramic-coated versions featuring the company’s proprietary Insutect™ coating – have been specially engineered to stop stray electric current in its tracks.

Schaeffler OPTIME Ecosystem

Schaeffler has combined its award-winning OPTIME condition monitoring system – featuring the OPTIME 5 and OPTIME 5 Ex sensor variants that enable wireless condition monitoring in a variety of manufacturing settings, including hazardous environments – with the company’s intelligent, automated OPTIME C1 lubricator to create a versatile all-in-one solution: the OPTIME Ecosystem. This cost-effective predictive maintenance solution efficiently and sustainably minimizes downtimes and high maintenance costs in production facilities.

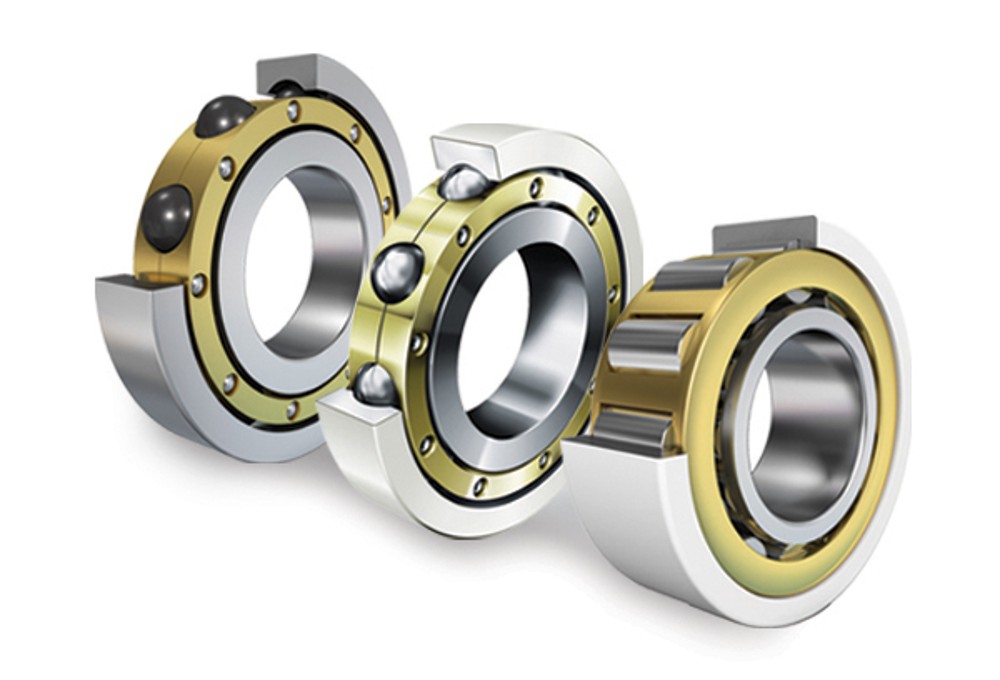

FAG X-life Angular-Contact Ball Bearings

FAG X-life single-row angular contact ball bearings from Schaeffler offer up to 30% higher dynamic load rating, as much as 50% longer rating life, and up to 10% less friction vs. conventional bearings.

Schaeffler Induction HEATERS

Available in tabletop and floor-standing versions, Schaeffler’s versatile HEATER-SMART and HEATER-BASIC series of induction heaters offer installation professionals from the electric motor repair industry the ability to safely heat workpieces ranging in weight between 20 kg/44 lbs. and 1,600 kg/3,527 lbs.

Tools for Safely Mounting and Dismounting Bearings

Schaeffler’s portfolio of devices for mounting and removing bearings includes tool sets for the safe and proper mounting of ball bearings on a shaft – complete with mounting rings, recoilless hammer and impact bushings. For removing small and medium-size bearings, Schaeffler offers self-centering mechanical pullers with up to 110 kN of pulling force. Larger bearings are easily removed with Schaeffler hydraulic pullers that can generate up to 490 kN of pulling force.

In addition to Schaeffler’s presence on the trade show floor, Frank Mignano, Schaeffler condition monitoring manager for the Americas, will be participating in EASA 2023’s “Peer to Peer: Leveraging New Technologies” session on Monday, June 26, beginning at 9:45 a.m. Frank will be presenting a real-life case study detailing how the Schaeffler OPTIME wireless condition monitoring system prevented the catastrophic and costly failure of a 3,000-hp electric motor.

About the EASA Convention & Solutions Expo

Produced by the Electrical Apparatus Service Association (EASA), the EASA Convention and Solutions Expo is the premier annual education, networking and exhibition event for the worldwide electromechanical repair industry.

Schaeffler is located in booth #1100 at the Gaylord National Resort & Convention Center in National Harbor, Maryland.

Publisher: Schaeffler Group USA Inc.

Country: USA

Usage of Schaeffler press pictures

Schaeffler press pictures may only be used for editorial purposes. Unless otherwise stated, all copyrights and rights of use and exploitation are owned by Schaeffler Technologies AG & Co. KG, Herzogenaurach (Germany) or by one of its affiliated companies. The reproduction and publication of Schaeffler press pictures is only permitted if the source is stated as follows: "Image: Schaeffler". The pictures may be used free of charge in such cases. The use of pictures for advertising or other commercial purposes, in particular their disclosure to third parties for commercial purposes, is hereby prohibited. Pictures may only be edited with the approval of Schaeffler.

We kindly request that a specimen copy be sent to us when Schaeffler press pictures are published in printed media (or a digital copy in the case of publication in electronic media). When using Schaeffler press pictures in films, please notify us and state the title of the film.

Use and utilization of Schaeffler press pictures is subject to the substantive laws of Germany without its conflict of law provisions. The place of competent jurisdiction shall be Nuremberg, Germany.

Postal adress:

Schaeffler Technologies AG & Co. KG

Corporate Communication

Industriestraße 1-3

91074 Herzogenaurach

Germany

Press releases

Package (Press release + media)